1 / 3

1 / 3Automated Palletizing from Conveyor Belt with Fairino FR20

ราคาฮาร์ดแวร์:

DOF

6

Max. reach

1,854

mm

Max. payload

20

kg

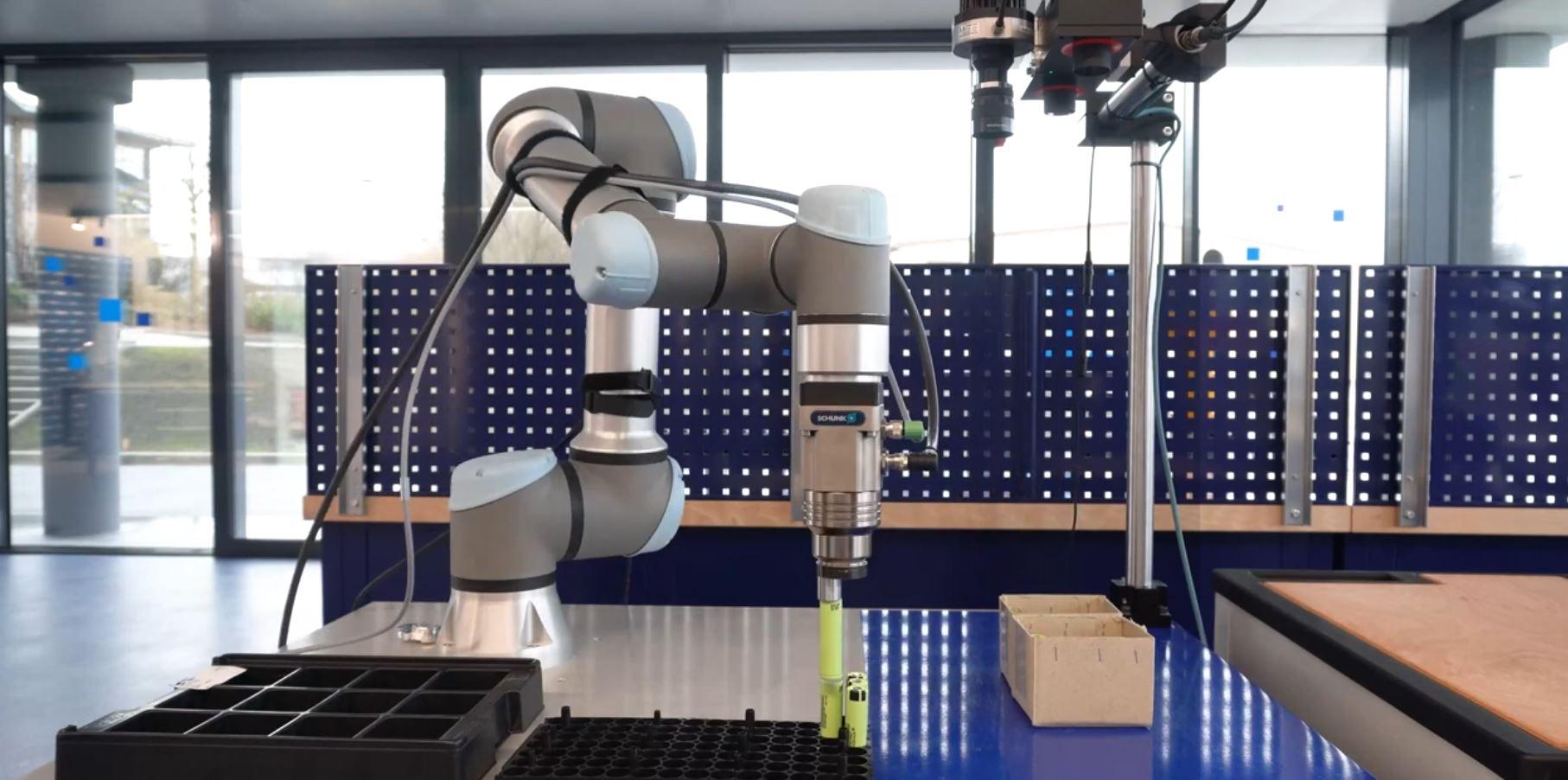

Seamless Conveyor-Based Palletizing with Fairino FR20 Collaborative Robot

In this application, the Fairino FR20 collaborative robot automates palletizing tasks directly from a conveyor belt. Products are continuously picked from the moving conveyor and stacked onto pallets with precision, ensuring an efficient and uninterrupted workflow. With a 20 kg payload capacity and intelligent motion control, the FR20 supports high-speed operations while maintaining consistent accuracy. Its ability to integrate flexibly with conveyor systems and adapt to various palletizing patterns makes it ideal for dynamic production environments. This solution boosts productivity and enhances process reliability, while reducing manual handling and labor costs.

What is the Application?

The system automates conveyor-driven palletizing, streamlining operations in industries like logistics, manufacturing, and packaging.

What are the Advantages of the Solution?

High-Speed Efficiency: Processes products quickly without interruptions.

Enhanced Accuracy: Guarantees consistent stacking for product safety.

Flexible Integration: Adapts to conveyor systems and diverse workflows.

What are the Advantages of the Robot?

The Fairino FR20 excels in palletizing operations with:

Robust Load Capacity: Handles items up to 20 kg effortlessly.

Dynamic Motion Control: Synchronizes seamlessly with conveyor speeds.

Adaptability: Allows customization for varying palletizing patterns.

Optimizing Production with Conveyor-Based Robotics

The Fairino FR20 collaborative robot offers a reliable and scalable solution for automating palletizing directly from conveyor belts. By combining speed, precision, and adaptability, it delivers enhanced workflow efficiency and operational reliability in fast-paced production environments, reducing labor demands and maximizing output.

2 ชิ้นส่วน