1 / 3

1 / 3Plant for powder coating of steel sheet cabins

Hardware Price:

Weight

light

Antistatic

Texture

Dirt resistant

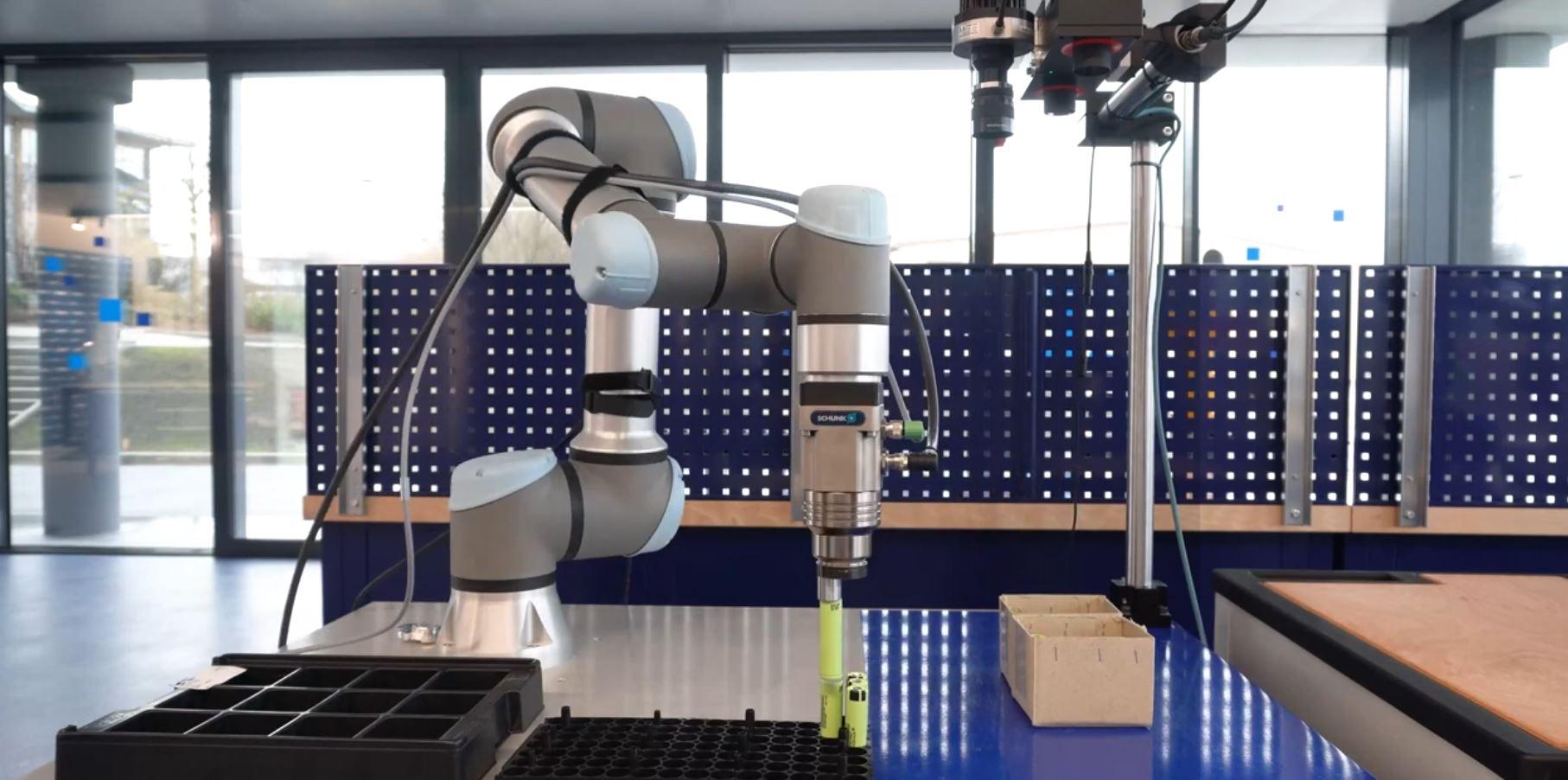

Powder Coating Optimization with igus Individual Axes and Robot Control

Precise positioning of spray lances is crucial for ensuring consistent powder coating results across various applications. In this setup, individual axes from igus allow flexibility in positioning spray lances to achieve the required coating patterns. By leveraging igus Robot Control, the axes can be easily programmed to move to specific positions, enabling seamless operation and customization across diverse coating workflows.

What is the Application?

The system automates positioning of spray lances for powder coating tasks, supporting efficient and consistent coverage for manufacturing and surface treatment processes.

What are the Advantages of the Solution?

Customizable Movements: Individual axes allow precise positioning for optimal coating performance.

Ease of Programming: igus Robot Control simplifies motion adjustments for different setups.

Enhanced Versatility: Adapts to varied coating requirements across industries.

What are the Advantages of the Robot?

The igus system offers robust capabilities for powder coating:

High Precision: Ensures accurate positioning for consistent coating quality.

Flexible Integration: Fits seamlessly into existing production setups.

Efficient Workflow: Reduces downtime by enabling quick adjustments.

Advancing Powder Coating Processes with igus Flexibility

The igus individual axes and Robot Control system provide a reliable solution for automating spray lance positioning in powder coating applications. With precise motion control and easy programmability, this system enhances efficiency, reduces costs, and ensures high-quality coating results for modern industries.

1 Component