1 / 3

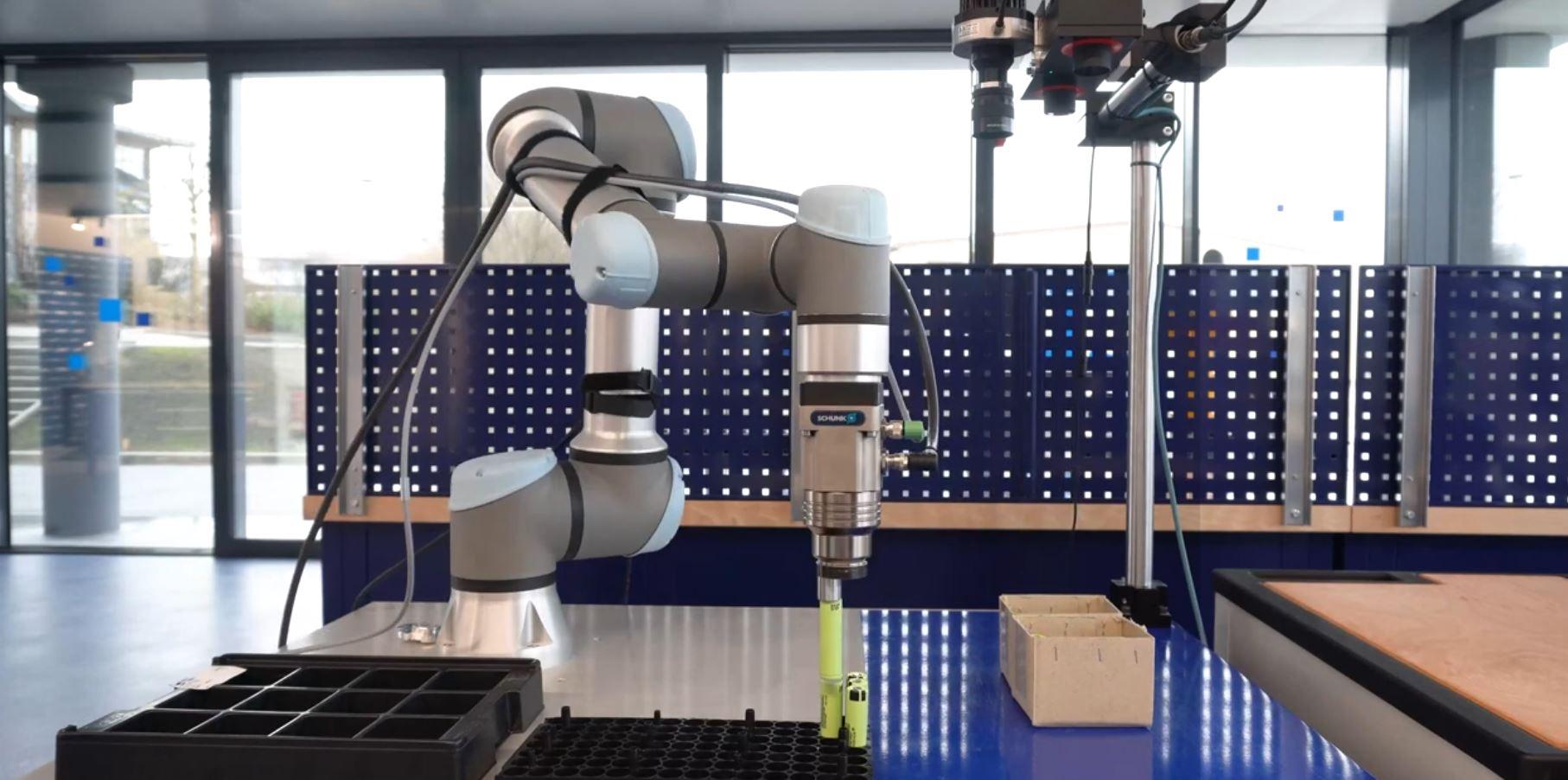

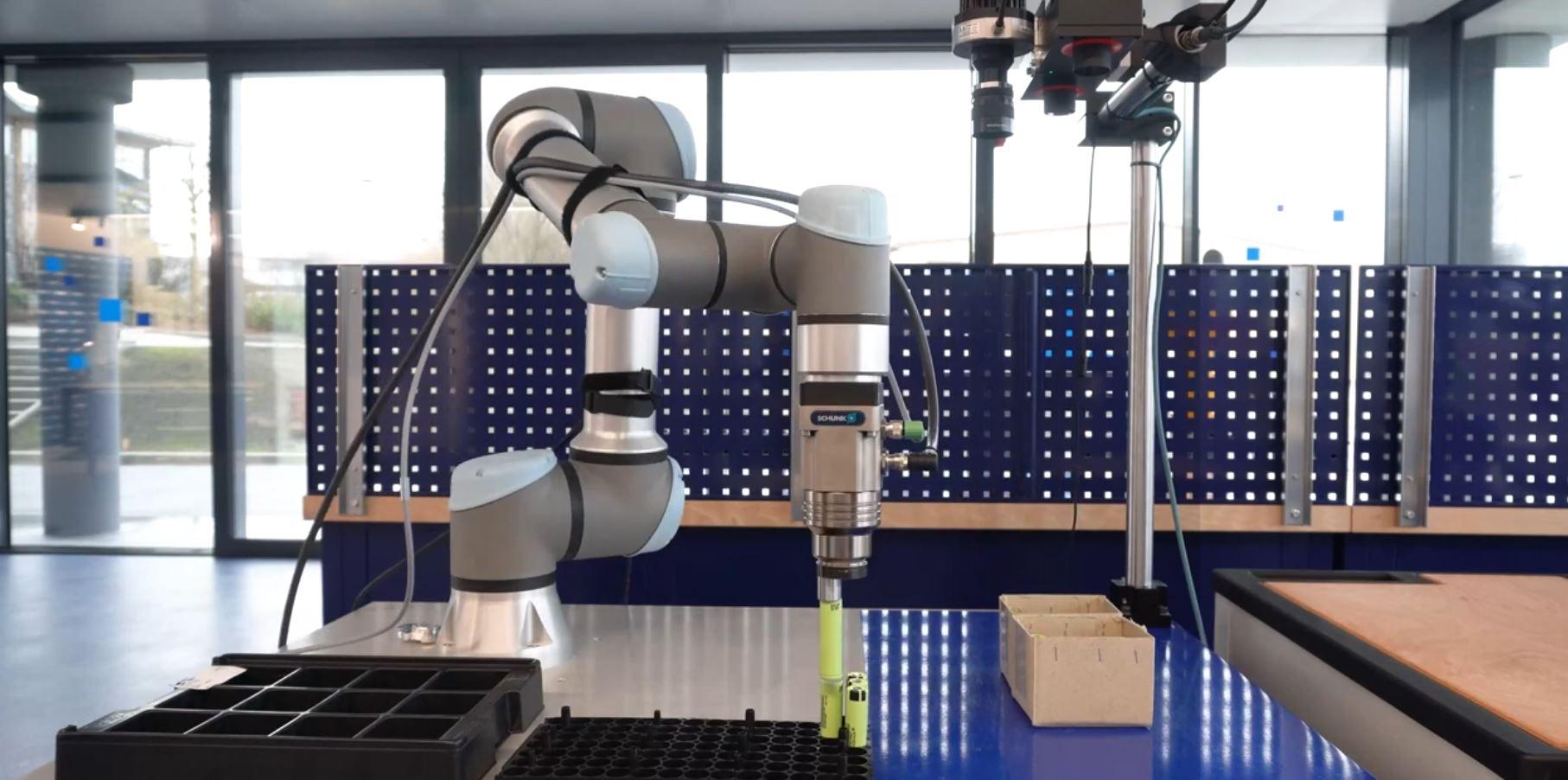

1 / 3Pick and Place with Schunk Magnetic Grippers

Hardware Price:

DOF

6

Repeatability

0.03

mm

Max. reach

850

mm

Camera-Based Pick-and-Place Automation with UR5e and Schunk EMH Gripper

Automating the handling of ferromagnetic workpieces requires precision, reliability, and energy efficiency. In this Schunk application, the UR5e articulated arm robot pairs with the compact Schunk EMH electro-permanent magnetic gripper and a camera-based vision system to execute intelligent pick-and-place tasks. This setup ensures high holding forces, even during an emergency stop, making it ideal for demanding industrial environments.

What is the Application?

The system automates pick-and-place processes, combining a vision system with magnetic gripping to handle ferromagnetic workpieces efficiently, supporting assembly, sorting, or packaging applications.

What are the Advantages of the Solution?

Energy Efficiency: Electro-permanent magnet enables low-energy operations while retaining force reliably.

High Flexibility: Adaptable to varied workpieces and processes.

Compact Design: Easy integration within tight production setups.

What are the Advantages of the Robot?

The UR5e robotic arm delivers robust automation capabilities:

Precise Movements: Handles workpieces with consistent accuracy using vision guidance.

Reliability: Maintains operation safety during emergency stops.

Scalable Integration: Adapts easily to complex workflows and environments.

Enhancing Productivity with Intelligent Automation

The integration of the Schunk EMH gripper and UR5e robot delivers a seamless solution for automated handling of ferromagnetic workpieces. By combining energy-efficient technologies, adaptive robotics, and advanced cameras, this system enhances production reliability, minimizes downtime, and enables high-speed, flexible automation for diverse industrial processes.

3 Components