1 / 3

1 / 3Camera-assisted component separation

Hardware Price:

DOF

4

Max. payload

1.5

kg

ROI

1 - 3

months

Efficient Automation with Variobotic: Intelligent Bin Picking Solution

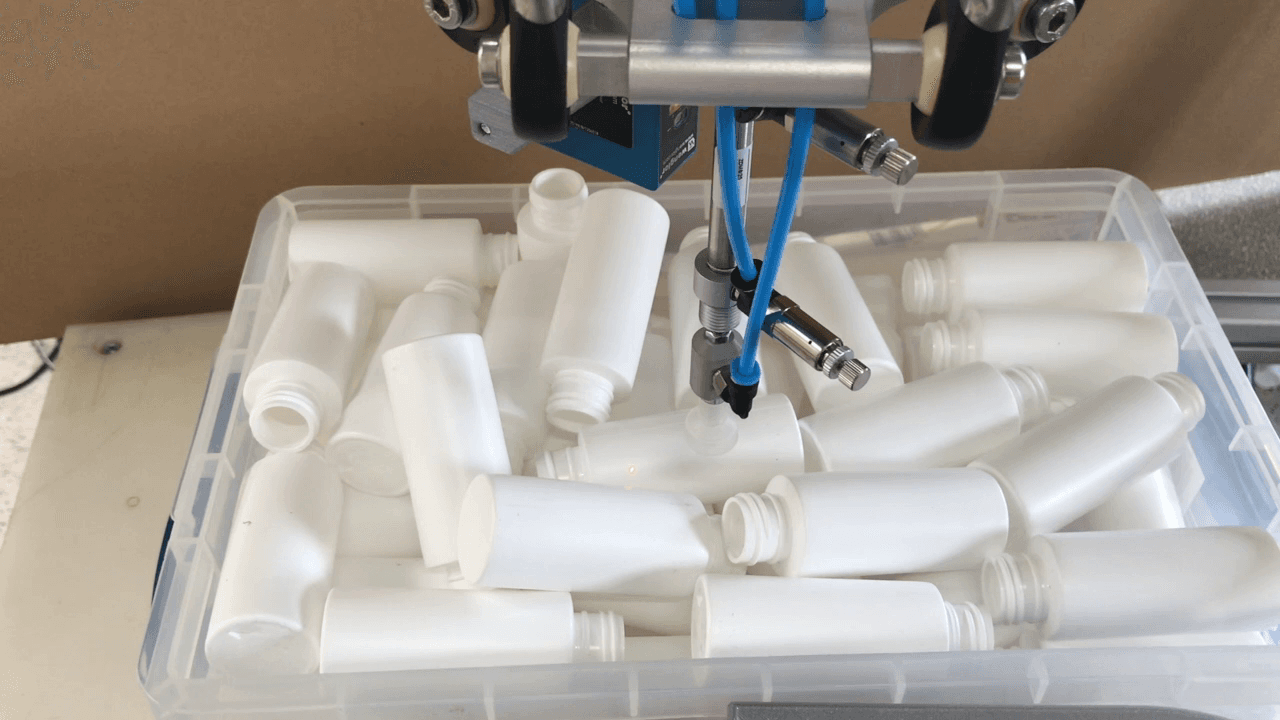

Automating complex workflows in manufacturing often requires precision and flexibility. This Variobotic application example from the bin picking sector successfully automates multiple steps using an integrated system. Components are first dropped onto the Varioshaker 270, which separates them using vibration. A vision system identifies individual parts and transmits the data to a Dobot robotic arm equipped with an EGP end effector, enabling precise pick-and-place operations for further processing steps.

What is the Application?

The system automates bin picking processes, handling unsorted components efficiently by separating, recognizing, and moving them to subsequent operations, such as assembly or packaging.

What are the Advantages of the Solution?

Improved Efficiency: Eliminates the need for manual sorting of components.

High Precision: Vision system ensures accurate part detection and reliable handling.

Versatile Integration: Compatible with various components and workflows.

What are the Advantages of the Robot?

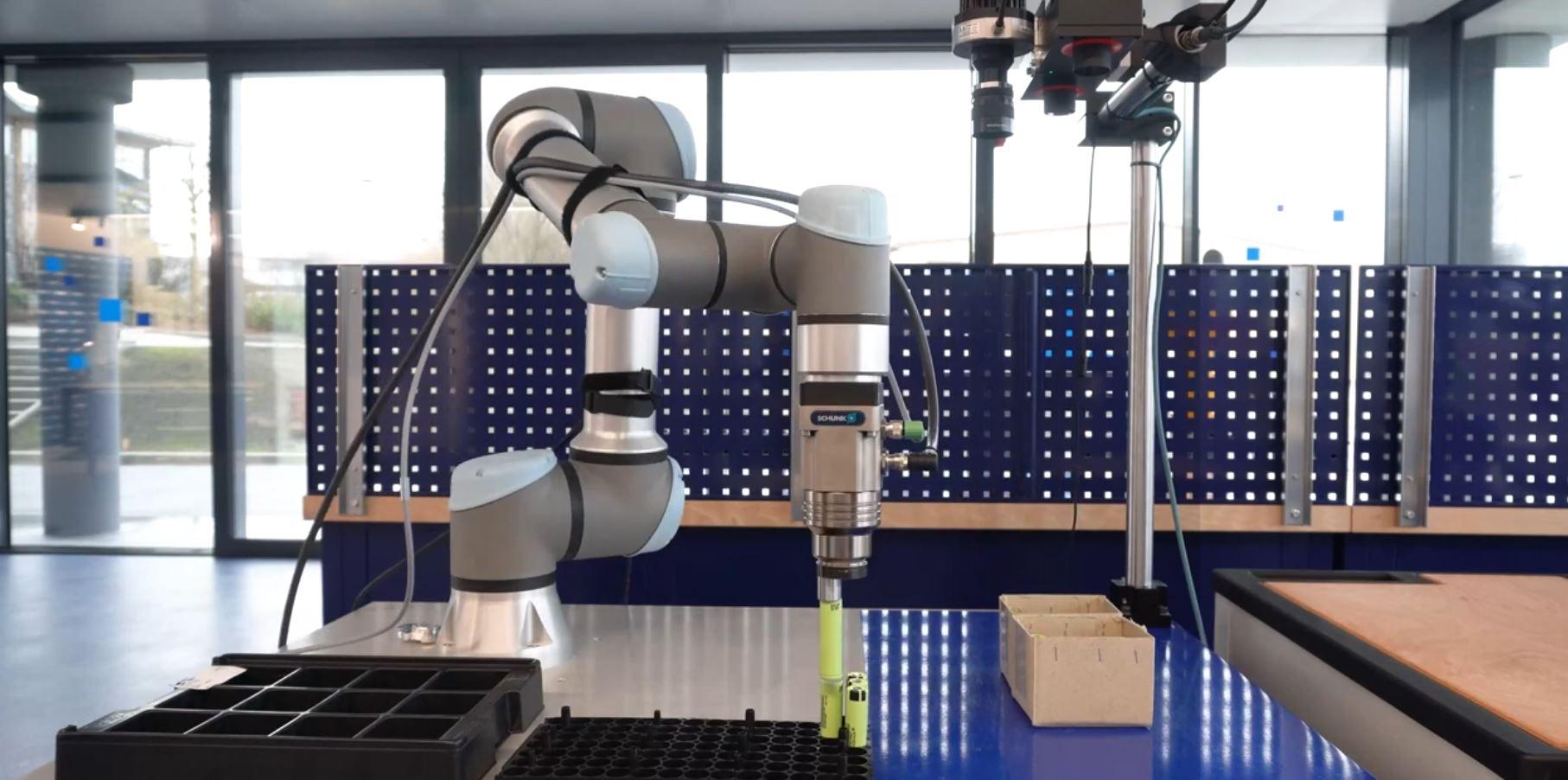

The Dobot robotic arm, paired with the EGP end effector, delivers advanced performance:

Flexible Handling: Adapts to different component shapes and sizes.

Precise Movements: Ensures repeatable and accurate handling for diverse tasks.

Compact Design: Fits easily into limited production spaces.

Transforming Bin Picking with Intelligent Automation

This solution from Variobotic combines the Varioshaker, vision system, and Dobot robotic arm to deliver a seamless bin picking process. By automating sorting and handling steps, it enhances precision, reduces labor costs, and speeds up production workflows, proving to be a scalable and efficient automation tool for modern manufacturing environments.

4 Components