Three things to consider when automating quality control

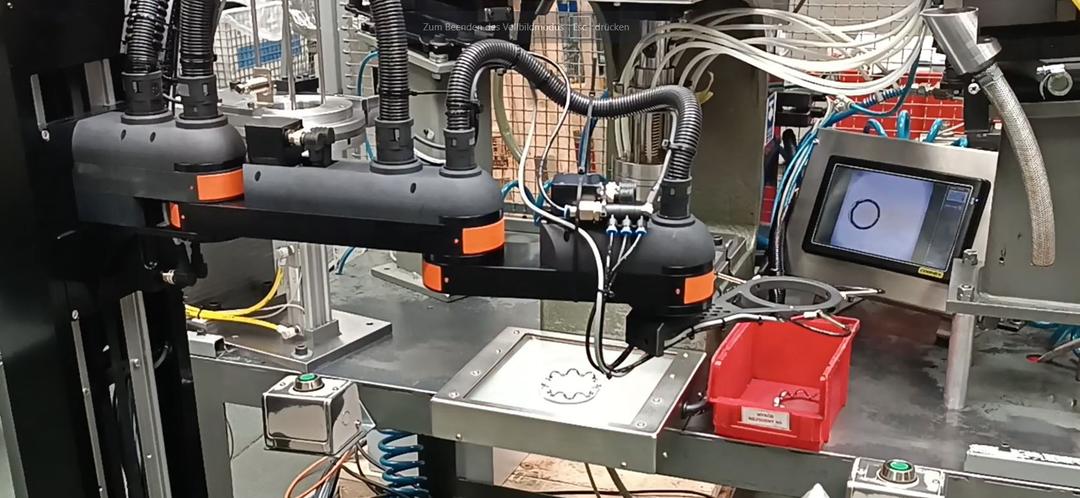

In modern manufacturing, quality is no accident – it is the result of precise processes and consistent control. However, manual quality control is often time-consuming, subjective and prone to errors. The solution: automation with robots.

With the modular, cost-effective robotics solutions from igus and the RBTX marketplace, inspection processes can be efficiently automated – from visual inspection and measurement to documentation.

Three things to consider when automating quality control

Choose the right sensor and camera technology

Whether 2D camera, 3D scanner, laser measurement or force sensor – choosing the right inspection technology depends heavily on the type of feature being inspected. It is important that the sensor technology and robot are perfectly coordinated.

Clearly define inspection criteria and tolerances

Automated systems require clear, measurable specifications. Which dimensions, surface characteristics or positions should be inspected? The more precise the requirements, the more reliable the test result.

Collect and document data

A major advantage of automated quality control is complete traceability. Robots can automatically store and analyse measurement results and integrate them into existing systems (e.g. ERP or MES).

How to get started with automating your quality control

Discover the keys to automating your quality control by analyzing your inspection process, comparing solutions, leveraging expert consulting, testing the setup, and ensuring seamless integration with training

Analyse the inspection process

Which characteristics need to be inspected? Which technologies are suitable?

Compare solutions

At RBTX.com, you will find tested complete solutions – including robots, cameras, sensors and control systems.

Take advantage of our consulting services

Our experts will help you select the right components – free of charge and independently of manufacturers.

Have it tested

With the RBTX testing service, you can have your application tested in advance – with real robots.

Integration & training

igus provides support during commissioning and offers practical training for your team.

RBTXpert Conclusion

Many people shy away from quality control with robots because they think: 'It's far too expensive. But I can tell you from experience: if you calculate what manual inspections cost you - time, labour, errors, rework - then the calculation looks completely different. Entry-level solutions are available from around €7,000. And if you check hundreds of parts every day, you'll often recoup this in a few months. My tip: don't just calculate the purchase price - calculate what you save every day when the robot takes over. And then you'll see: Quality pays off.

Advantages of automation over manual quality control

Automated quality control offers objective inspection, faster evaluation, fewer errors, complete documentation, and reduced workload for employees

Objectivity

Robots inspect according to exactly the same criteria – regardless of their daily form or experience.

Higher inspection speed

Automated systems inspect faster and continuously – even in 24/7 operation.

Error reduction

Precise sensor technology and repeat accuracy significantly reduce the error rate.

Complete documentation

All inspection data can be automatically stored and evaluated.

Reduced workload for employees

No more monotonous visual inspections or manual measurements – more focus on value-adding activities.

Get started, find your solution now!

igus GmbH

igus GmbH

Fairino

CNRS

HTL Rennweg

STP Group

TOHO POLAND Sp. z o.o.

CobotEx Sp. z o. o.

FAQ

Frequently asked questions about automated quality control